- Avia

- Allison Transmission

- Aichi

- Astra

- BAW

- BOBCAT

- Case

- Caterpillar

- Crown

- Cummins

- Challenger

- Claas

- Daewoo

- DAF

- Daihatsu

- Detroit Diesel

- Deutz

- Dongfeng

- Doosan

- Eaton

- Fendt

- Freightliner

- Hino

- Hyundai

- Iveco

- JCB

- JAC

- John Deere

- Jungheinrich

- Kenworth

- KIA

- Kubota

- Mack

- Man

- Massey Ferguson

- Mercedes

- Mitsubishi

- NEW HOLLAND

- Nissan

- Paccar

- Perkins

- Peterbilt

- Renault

- Scania

- Shaanxi

- Shacman Fault Codes

- Toyota Forklift

- VAG

- Volvo

- Webasto

Daewoo Trucks and Forklifts Service & Repair Manuals

General information

Engine characteristics

Main data and specifications

Engine specification(’98 type)

Engine performance curve

Exterior view of engine

Major maintenance

Preventive maintenance

Diagnostics and troubleshooting

for the engine

Disassembly and reassembly of major components

Disassembly

Inspection

Reassembly

Breaking-in

Scan pole diagnosis for DE12TIS

Wire harness connection

Sensor data

System & Vehicle selection

Actuator test

Self-diagnosis(current)

Flight record

Service Manual

G420E/G424E Tier LP Engine

Lift Trucks

G15S-2, G18S-2, G20SC-2

GC15S-2, GC18S-2, GC20SC-2

With G420E Tier LP Engine

G20E-3, G25E-3, G30E-3, G32E-3

GC20E-3, GC25E-3, GC30E-3, GC32E-3

with G424E Tier LP Engine

LPG AND LPG FUEL TANKS

ENGINE SPECIFICATION

MI-04 LPG SYSTEM OPERATIONAL OVERVIEW

MI-04 MAINTENANCE SCHEDULE

MI-04 LP BASIC TROUBLESHOOTING

MI-04 LP ADVANCED DIAGNOSTICS

MI-04 ELECTRICAL CONNECTIONS

N2001 PRESSURE REGULATOR /CONVERTER

N-CA55-500TR AIR/FUEL MIXER

TEST AND ADJUSTMENTS

SERVICE TOOL KIT

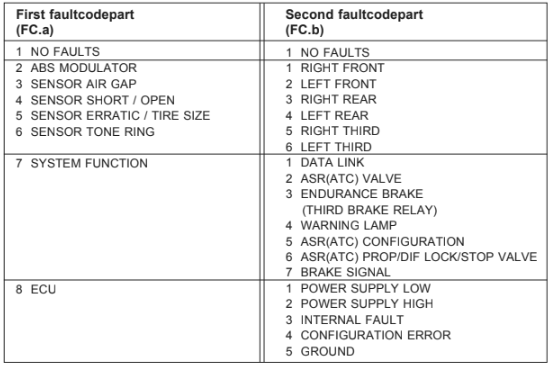

FAULTCODES / REPAIR INSTRUCTIONS

2. n Check modulator wires. Inlet(EV) or outlet(AV) or common wire is permanently or

temporarily broken or shorted to plus respectively ground.

3. n Amplitude of sensorsignal is to low. Check bearing play, polewheel run out, push sensor

to polewheel. Check sensor wiring and connectors for intermittent contact. Other possible

reason:gear engaged at slippery conditions. 16 sec. slip duration.

4. n Check sensor wiring. Open circuit, short circuit to plus respectively ground or between

sensorwires IG/IGM is detected

5. n Check sensor wiring and connectors for intermittent contact. Check toothed wheel for

damages. Check for mismatch-fault of another sensor. Pneus or number of polewheel

teeth are different.

6. n Check polewheel for damages/missing teeth/run out. Use WABCO sensor probe. Replace

polewheel if not checked o. k. If additional airgap faults are stored, adjust airgap.

7-1 ECU with PROP : Check wire and speedometer signal. C3/B7 signal calibration, check

tyre sizes.

Gear switch signals neutral or is manipulated.

Electronic engine control: Check wiring respectively other ECU's

Excessive slip / dynotester ? One axle was much faster than other?

7-2 Check wire. Output wire is interrupted or grounded or shorted to battery supply.

Check wire. Output wire is interrupted or grounded or shorted to battery supply.

ECU with SAE J1922 resp. SAE J1939:Check other ECU's. No access to the link

7-3

7-4 Check wire and bulb. Was blinkcode switch activated longer than 16 s?

Check wires resp. parametersetting. Diff-brake valve without engine control is detected or

CAN, PWM, PROP are detected while selfparameterizing is disabled.

7-5

7-6 Check wire. Output wire is interrupted or shorted to ground or battery supply.

7-7 Check brake sensor wiring. Intput wire is interrupted or shorted to ground or battery supply.

8-1 Check supply wire and fuse. Supply voltage is temporarily too low

8-2 Check alternator and battery. Supply voltage too high for more than 5 sec.

8-3 Replace ABS(ASR) electronic if fault detection repeats.

8-4 No modulators connected or wrong ECM or wrong parameterized

8-5 Check ECU ground wires and common modulator wires

BLINKCODE LIST

SERVICE ELECTRIC EQUIPMENTS FOR USER CIRCUIT DIAGRAM

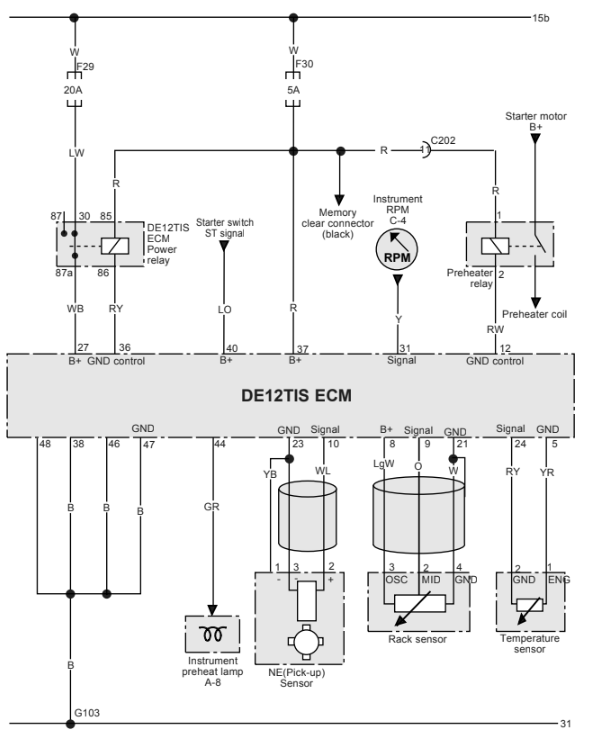

DE12TIS ECM POWER, RACK SENSOR, RPM SENSORCIRCUIT DIAGRAM

DAEWOO CONNECTOR AND PIN NUMBER