- Avia

- Allison Transmission

- Aichi

- Astra

- BAW

- BOBCAT

- Case

- Caterpillar

- Crown

- Cummins

- Challenger

- Claas

- Daewoo

- DAF

- Daihatsu

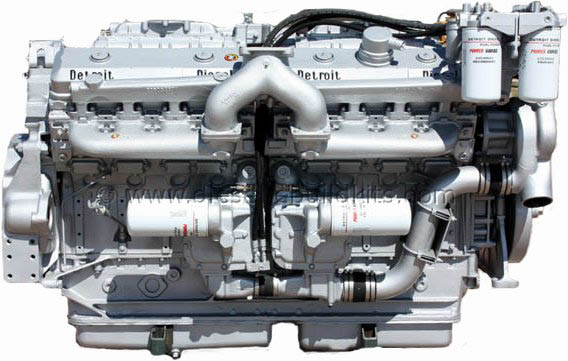

- Detroit Diesel

- Deutz

- Dongfeng

- Doosan

- Eaton

- Fendt

- Freightliner

- Hino

- Hyundai

- Iveco

- JCB

- JAC

- John Deere

- Jungheinrich

- Kenworth

- KIA

- Kubota

- Mack

- Man

- Massey Ferguson

- Mercedes

- Mitsubishi

- NEW HOLLAND

- Nissan

- Paccar

- Perkins

- Peterbilt

- Renault

- Scania

- Shaanxi

- Shacman Fault Codes

- Toyota Forklift

- VAG

- Volvo

- Webasto

Detroit Diesel Engines Service Repair Manuals

Detroit Diesel Content Example

1 ROCKER COVER

1.1 DESCRIPTION AND OPERATION OF ROCKER COVER AND RELATED PARTS

1.2 REMOVAL OF THE ROCKER COVER

1.3 CLEANING AND INSPECTION OF THE ROCKER COVER

1.4 INSTALLATION OF THE ROCKER COVER

2 CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

2.1 DESCRIPTION AND OPERATION OF CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY AND RELATED PARTS

2.2 REMOVAL OF CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

2.3 INSPECTION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

2.4 INSTALLATION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

2.5 DD13 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS FUEL FROM COOLER AFTER ENGINE BRAKE SOLENOID FAILURE

2.6 DD15 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS FUEL FROM COOLER AFTER ENGINE BRAKE SOLENOID FAILURE

3 CAMSHAFT HOUSING

3.1 REMOVAL OF THE CAMSHAFT HOUSING

3.2 INSPECTION OF CAMSHAFT HOUSING

3.3 INSTALLATION OF THE CAMSHAFT HOUSING

4 CAMSHAFT TIMING

4.1 CAMSHAFT TIMING VERIFICATION

4.2 TIMING THE CAMSHAFTS WITH THE GEAR TRAIN INSTALLED

5 GEAR TRAIN AND ENGINE TIMING

5.1 DESCRIPTION AND OPERATION OF GEAR TRAIN AND RELATED PARTS

5.2 ENGINE GEAR TRAIN INSTALLATION AND TIMING

5.3 CHECKING AND ADJUSTING GEAR LASH WITH CAMSHAFT HOUSING REMOVED

6 WATER MANIFOLD

6.1 DESCRIPTION AND OPERATION OF DD15 & DD16 WATER MANIFOLD AND RELATED COMPONENTS

6.2 REMOVAL OF THE DD15 & DD16 WATER MANIFOLD

6.3 CLEANING AND INSPECTION OF THE DD15 & DD16 WATER MANIFOLD

6.4 INSTALLATION OF THE DD15 & DD16 WATER MANIFOLD

6.5 DD13 EXHAUST GAS RECIRCULATION COOLER WATER MANIFOLD ASSEMBLY

7 COLD BOOST PIPE (CHARGE AIR PIPE)

7.1 DESCRIPTION AND OPERATION OF COLD BOOST PIPE (CHARGE AIR PIPE) AND RELATED COMPONENTS

7.2 REMOVAL OF THE COLD BOOST PIPE (CHARGE AIR PIPE)

7.3 INSPECTION OF COLD BOOST PIPE (CHARGE AIR PIPE)

7.4 INSTALLATION OF THE COLD BOOST PIPE (CHARGE AIR PIPE)

8 AIR INTAKE MANIFOLD

8.1 DESCRIPTION AND OPERATION OF AIR INTAKE MANIFOLD AND RELATED PARTS

8.2 REMOVAL OF AIR INTAKE MANIFOLD

8.3 CLEANING OF THE AIR INTAKE MANIFOLD

8.4 INSPECTION OF THE AIR INTAKE MANIFOLD

8.5 INSTALLATION OF AIR INTAKE MANIFOLD

9 DD13 TURBOCHARGER

9.1 DESCRIPTION AND OPERATION OF THE DD13 TURBOCHARGER AND RELATED PARTS

9.2 REMOVAL OF THE DD13 TURBOCHARGER

9.3 INSPECTION OF THE DD13 TURBOCHARGER

9.4 INSTALLATION OF THE DD13 TURBOCHARGER

9.5 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS FUEL FROM COOLER AFTER DD13 TURBOCHARGER FAILURE

10 DD13 WASTEGATE SOLENOID

10.1 DESCRIPTION AND OPERATION OF THE DD13 WASTEGATE SOLENOID

10.2 REMOVAL OF THE DD13 WASTEGATE SOLENOID

10.3 INSTALLATION OF THE DD13 WASTEGATE SOLENOID

11 DD15 TURBOCHARGER

11.1 DESCRIPTION AND OPERATION OF TURBOCHARGER AND RELATED PARTS

11.2 REMOVAL OF DD15 TURBOCHARGER

11.3 INSPECTION OF DD15 TURBOCHARGER

11.4 INSTALLATION OF DD15 TURBOCHARGER

11.5 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS OIL FROM EGR COOLER AFTER DD15 TURBOCHARGER FAILURE

12 DD15 AXIAL POWER TURBINE

12.1 DESCRIPTION AND OPERATION OF DD15 AXIAL POWER TURBINE AND RELATED PARTS

12.2 REMOVAL OF DD15 AXIAL POWER TURBINE

12.3 INSPECTION OF THE DD15 AXIAL POWER TURBINE

12.4 INSTALLATION OF DD15 AXIAL POWER TURBINE 7

13 DD15 AXIAL POWER TURBINE GEAR BOX

13.1 DESCRIPTION AND OPERATION OF DD15 AXIAL POWER TURBINE GEAR BOX AND RELATED PARTS

13.2 REMOVAL OF THE DD15 AXIAL POWER TURBINE GEAR BOX

13.3 INSPECTION OF DD15 AXIAL POWER TURBINE GEAR BOX

13.4 INSTALLATION OF THE AXIAL POWER TURBINE GEAR BOX

14 CYLINDER HEAD

14.1 DESCRIPTION AND OPERATION OF CYLINDER HEAD AND RELATED PARTS

14.2 REMOVAL OF THE DD13 CYLINDER HEAD

14.3 INSTALLATION OF THE DD13 CYLINDER HEAD

14.4 REMOVAL OF THE DD15 CYLINDER HEAD

14.5 CLEANING OF THE CYLINDER HEAD

14.6 ASSEMBLY OF CYLINDER HEAD

14.7 INSTALLATION OF THE DD15 CYLINDER HEAD

14.8 REMOVAL OF VALVE SPRING (CYLINDER HEAD INSTALLED)

14.9 REMOVAL OF THE VALVE SPRING (CYLINDER HEAD REMOVED)

14.10 REMOVAL OF INTAKE AND EXHAUST VALVES

14.11 CLEANING OF VALVES AND RELATED PARTS

14.12 INSPECTION OF VALVE SPRINGS

14.13 INSPECTION OF VALVE

14.14 INSTALLATION OF VALVE, SPRING, SEAL AND VALVE CAP

14.15 VALVE LASH ADJUSTMENTS

14.16 SETTING THE ENGINE BRAKE LASH

15 PISTON AND CONNECTING ROD ASSEMBLY

15.1 DESCRIPTION AND OPERATION OF PISTON AND CONNECTING ROD AND RELATED PARTS

15.2 REMOVAL OF PISTON AND CONNECTING ROD ASSEMBLY

15.3 DISASSEMBLY OF PISTON AND CONNECTING ROD ASSEMBLY

15.4 INSPECTION OF PISTON AND CONNECTING ROD ASSEMBLY

15.5 ASSEMBLY OF PISTON AND CONNECTING ROD ASSEMBLY

15.6 INSTALLATION OF PISTON AND CONNECTING ROD ASSEMBLY

16 CYLINDER LINER

16.1 DESCRIPTION AND OPERATION OF CYLINDER LINER AND RELATED PARTS

16.2 REMOVAL OF CYLINDER LINER

16.3 INSPECTION OF CYLINDER LINER

16.4 CLEANING OF THE CYLINDER LINER

16.5 INSTALLATION OF THE CYLINDER LINER

17 CRANKSHAFT

17.1 DESCRIPTION AND OPERATION OF CRANKSHAFT AND RELATED PARTS

17.2 REMOVAL OF CRANKSHAFT

17.3 INSPECTION OF THE CRANKSHAFT AND RELATED PARTS

17.4 INSTALLATION OF CRANKSHAFT

17.5 REMOVAL OF CRANKSHAFT REAR OIL SEAL

17.6 INSTALLATION OF THE REAR OIL SEAL

17.7 REMOVAL OF THE CRANKSHAFT FRONT OIL SEAL

17.8 INSTALLATION OF THE CRANKSHAFT FRONT OIL SEAL

18 LUBRICATION SYSTEM

18.1 DESCRIPTION AND OPERATION OF THE LUBRICATION SYSTEM AND RELATED COMPONENTS

19 OIL PAN

19.1 DESCRIPTION AND OPERATION OF OIL PAN AND RELATED COMPONENTS

19.2 REMOVAL OF OIL PAN

19.3 CLEANING OF OIL PAN

19.4 INSPECTION OF OIL PAN

19.5 REMOVAL OF THREADED INSERT — PLASTIC OIL PAN ONLY

19.6 INSTALLATION OF THREADED INSERT — PLASTIC OIL PAN ONLY .

19.7 INSTALLATION OF OIL PAN

20 OIL DIPSTICK TUBE

20.1 DESCRIPTION AND OPERATION OF OIL DIPSTICK TUBE AND RELATED COMPONENTS

20.2 REMOVAL OF THE OIL DIPSTICK TUBE

20.3 INSTALLATION OF THE OIL DIPSTICK TUBE

21 OIL PUMP

21.1 DESCRIPTION AND OPERATION OF OIL PUMP AND RELATED COMPONENTS

21.2 REMOVAL OF THE OIL PUMP, OIL SUCTION MANIFOLD, AND OIL LINES

21.3 INSPECTION OF THE OIL PUMP, OIL SUCTION MANIFOLD, AND OIL LINES

21.4 INSTALLATION OF THE OIL PUMP, OIL SUCTION MANIFOLD, AND OIL LINES

22 CRANKCASE BREATHER

22.1 DESCRIPTION AND OPERATION OF CRANKCASE BREATHER

22.2 REMOVAL OF THE CRANKCASE BREATHER

22.3 INSPECTION OF THE CRANKCASE BREATHER

22.4 INSTALLATION OF THE CRANKCASE BREATHER

23 OIL FILTER

23.1 REPLACEMENT OF THE OIL FILTER

24 OIL SAMPLE VALVE

24.1 REPLACING OIL PLUG WITH OIL SAMPLE VALVE

24.2 REMOVAL OF OIL SAMPLE VALVE

24.3 INSTALLATION OF OIL SAMPLE VALVE

25 OIL FILLER NECK

25.1 REMOVAL OF THE OIL FILLER NECK

25.2 INSTALLATION OF THE OIL FILLER NECK

26 OIL COOLANT MODULE

26.1 DESCRIPTION AND OPERATION OF THE OIL COOLANT MODULE

26.2 REMOVAL OF THE OIL COOLANT MODULE

26.3 INSTALLATION OF THE OIL COOLANT MODULE

26.4 REMOVAL OF THE OIL THERMOSTAT

26.5 INSTALLATION OF THE OIL THERMOSTAT

27 PRIMING THE LUBRICATION SYSTEM

27.1 PRIMING THE ENGINE LUBRICATION SYSTEM

28 COOLING SYSTEM

28.1 DESCRIPTION AND OPERATION OF COOLING SYSTEM AND RELATED COMPONENTS

29 ENGINE WATER PUMP

29.1 DESCRIPTION AND OPERATION OF ENGINE WATER PUMP

29.2 REMOVAL OF THE WATER PUMP

29.3 INSPECTION OF THE WATER PUMP

29.4 INSTALLATION OF THE WATER PUMP

30 COOLANT THERMOSTAT

30.1 DESCRIPTION AND OPERATION OF COOLANT THERMOSTAT

30.2 REMOVAL OF COOLANT THERMOSTAT AND SEAL

30.3 INSPECTION OF COOLANT THERMOSTAT AND SEAL

30.4 INSTALLATION OF COOLANT THERMOSTAT AND SEAL

31 COOLANT FILTER

31.1 DESCRIPTION AND OPERATION OF COOLANT FILTER

31.2 REMOVAL OF THE COOLANT FILTER

31.3 INSTALLATION OF THE COOLANT FILTER

32 COOLANT FILTER SERVICE MODULE

32.1 REMOVAL OF COOLANT FILTER SERVICE MODULE

32.2 INSTALLATION OF COOLANT FILTER SERVICE MODULE

33 COOLANT INLET ELBOW

33.1 REMOVAL OF THE COOLANT INLET ELBOW

33.2 INSTALLATION OF THE COOLANT INLET ELBOW

34 FLYWHEEL AND FLYWHEEL HOUSING

34.1 DESCRIPTION AND OPERATION OF FLYWHEEL, FLYWHEEL HOUSING AND RELATED PARTS

34.2 REMOVAL OF FLYWHEEL HOUSING

34.3 INSTALLATION OF FLYWHEEL HOUSING

34.4 REMOVAL OF THE FLYWHEEL

34.5 INSPECTION OF FLYWHEEL

34.6 INSTALLATION OF FLYWHEEL

34.7 INSPECTION OF FLYWHEEL HOUSING AND REAR OIL SEAL AREA OF CRANKSHAFT

34.8 REMOVAL OF RING GEAR

34.9 INSTALLATION OF RING GEAR

35 FRONT ENGINE MOUNT/RADIATOR SUPPORT

35.1 DESCRIPTION AND OPERATION OF FRONT ENGINE MOUNT/RADIATOR SUPPORT AND RELATED PARTS

35.2 REMOVAL OF THE FRONT ENGINE MOUNT/RADIATOR SUPPORT

35.3 INSPECTION OF THE FRONT ENGINE MOUNT/RADIATOR SUPPORT

35.4 INSTALLATION OF THE FRONT ENGINE MOUNT/RADIATOR SUPPORT

36 VIBRATION DAMPER

36.1 REMOVAL OF THE VIBRATION DAMPER

36.2 INSTALLATION OF THE VIBRATION DAMPER

37 FRONT ENGINE COVER

37.1 DESCRIPTION AND OPERATION OF THE FRONT ENGINE COVER

37.2 REMOVAL OF THE FRONT ENGINE COVER

37.3 INSPECTION OF THE FRONT ENGINE COVER

37.4 INSTALLATION OF THE FRONT ENGINE COVER

38 ENGINE LIFTER BRACKETS

38.1 DESCRIPTION AND OPERATION OF ENGINE LIFTER BRACKETS AND RELATED PARTS

38.2 REMOVAL OF THE FRONT ENGINE LIFTER BRACKET WITHOUT FRONT ENGINE POWER TAKE-OFF

38.3 REMOVAL OF THE FRONT ENGINE LIFTER BRACKET WITH FRONT ENGINE POWER TAKE-OFF

38.4 REMOVAL OF THE REAR ENGINE LIFTER BRACKETS

38.5 INSPECTION OF THE ENGINE LIFTER BRACKETS

38.6 INSTALLATION OF THE REAR ENGINE LIFTER BRACKETS

38.7 INSTALLATION OF THE FRONT ENGINE LIFTER BRACKET WITHOUT FRONT ENGINE POWER TAKE-OFF

38.8 INSTALLATION OF THE FRONT ENGINE LIFTER BRACKET WITH FRONT ENGINE POWER TAKE-OFF

39 BELT DRIVE TENSIONER SYSTEM

39.1 DESCRIPTION AND OPERATION OF BELT DRIVE TENSIONER AND RELATED PARTS

39.2 REMOVAL OF THE BELT TENSIONER

39.3 INSTALLATION OF THE BELT TENSIONER

39.4 REMOVAL OF THE IDLER PULLEY AND IDLER PULLEY BRACKET

39.5 INSTALLATION OF THE IDLER PULLEY AND IDLER PULLEY BRACKET

39.6 REMOVAL OF NON-BRACKETED IDLER PULLEY

39.7 INSTALLATION OF NON-BRACKETED IDLER PULLEY

39.8 REMOVAL OF THE ACCESSORY MOUNTING BRACKET

39.9 INSTALLATION OF THE ACCESSORY MOUNTING BRACKET

40 POLY-V-BELTS

40.1 REMOVAL OF THE POLY-V-BELTS

40.2 INSPECTION OF THE POLY-V-BELTS

40.3 INSTALLATION OF THE POLY-V-BELTS

41 AIR COMPRESSOR

41.1 DESCRIPTION AND OPERATION OF THE AIR COMPRESSOR

41.2 REMOVAL OF THE AIR COMPRESSOR

41.3 INSPECTION OF THE AIR COMPRESSOR

41.4 INSTALLATION OF THE AIR COMPRESSOR

42 CYLINDER BLOCK

42.1 DESCRIPTION AND OPERATION OF CYLINDER BLOCK AND RELATED PARTS

42.2 REMOVAL AND DISASSEMBLY OF ENGINE FROM THE VEHICLE

42.3 CLEANING THE CYLINDER BLOCK

42.4 REASSEMBLY AND INSTALLATION OF CYLINDER BLOCK

Detroit Diesel Spare Parts Catalog

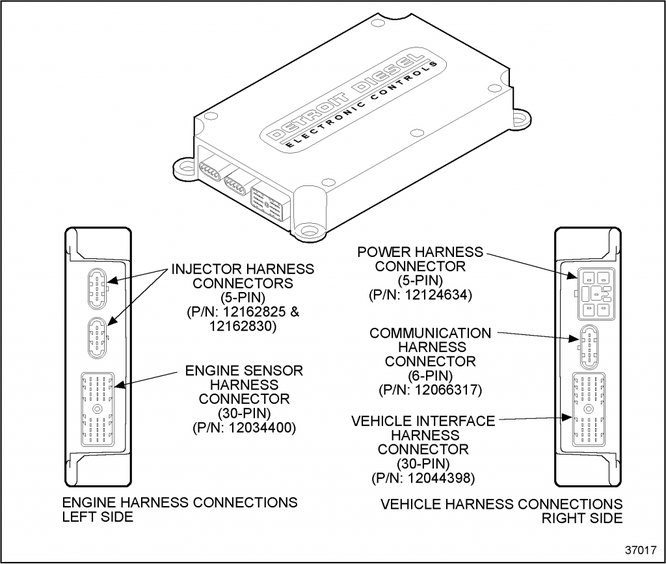

Detroit Diesel Engine Electrical Wiring Diagrams

DDEC III-IV Series 60 Schematic

Wiring diagram, Injector Harness Schematic

Schematic DDEC IV Series 60 MY2003 EGR

Engine Sensor Harness, Vehicle Interface Harness

DDEC V Series 60 EGR Schematic

Engine Harness, Vehicle Interface Harness

Scheme DDEC VI Series 60 MCM EGR

EPA07 Common powertrain controller (CPC),

Vehicle Interface Harness (VIH)

Connectors Detroit Diesel Electronic Control

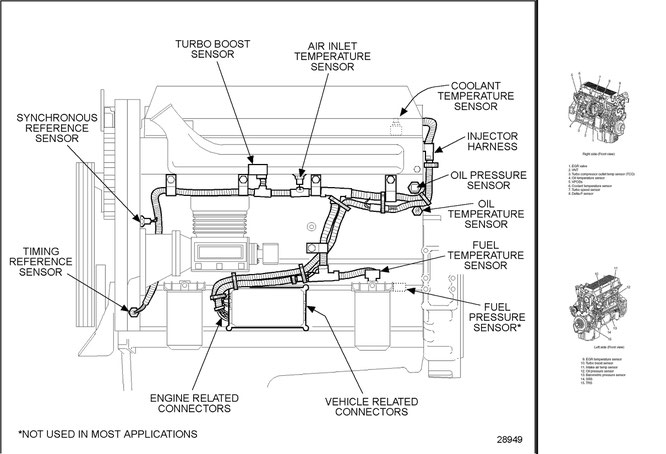

Detroit diesel 60 engine sensorsSensor Location

Reynier (Thursday, 16 September 2021 19:43)

Please I need the a/c diagram for 2007 freightliner columbia thanks